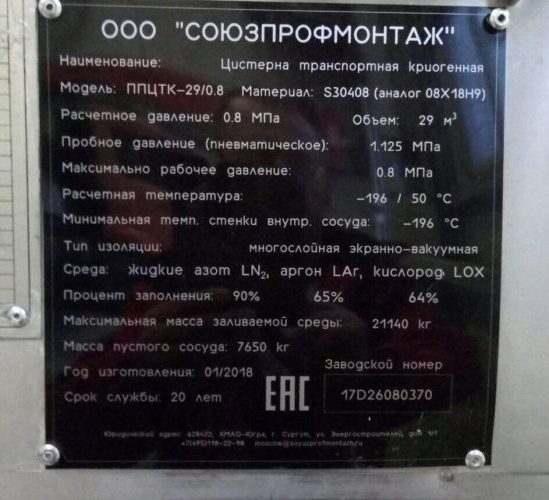

“Soyuzprofmontazh” LLC offers you equipment of our own production – semi-trailer Tanks of the following models: Semi-trailer Tank – 19/0,3; Semi-trailer Tank – 26/0,3; Semi-trailer Tank – 26/0,8; Semi-trailer Tank – 29/0,3; Semi-trailer Tank – 29/0,8; Semi-trailer Tank – 26/0,3-ISO40; Semi-trailer Tank – 26/0,8-ISO40; Semi-trailer Tank – 29/0,3-ISO40; Semi-trailer Tank – 29/0,8-ISO40

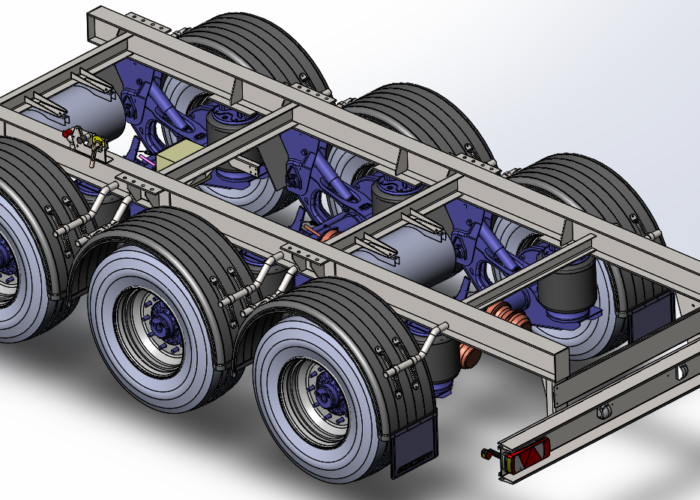

Semi-trailer cryogenic Tanks are manufactured on the basis of a three-axle trailer chassis (running gear) and is designed for transportation of cryogenic liquids: nitrogen, oxygen, argon.

All cryogenic Tanks of the Laron series are manufactured in accordance with the requirements of the technical regulations on the safety of wheeled vehicles, designed for the transportation of hazardous goods AT, OX EX/II, EX/III and FL (according to ADR classification), and also meet the requirements of the technical regulations of the Customs Union TR-TC-032/2013 “On the safety of equipment operating under excessive pressure.”

The model range, Table 1-1 – technical characteristics of semi-trailer Tanks LARON

| Model | Semi-trailer Tank -19/0,3 | Semi-trailer Tank -26/0,3 | Semi-trailer Tank -26/0,8 | Semi-trailer Tank -29/0,3 | Semi-trailer Tank -29/0,8 |

| Capacity, m3 | 19 | 26 | 26 | 29 | 29 |

| Loading mass, kg | 14 440 | 19 344 | 19 344 | 21 550 | 21 550 |

| Loading rate (nitrogen/oxygen), % | 0,95/0,67 | 0,95/0,67 | 0,95/0,67 | 0,92/0,66 | 0,92/0,66 |

| Design pressure, MPa | 0,3 | 0,3 | 0,8 | 0,3 | 0,8 |

| Design temperature, С° | – 196 | – 196 | – 196 | – 196 | – 196 |

| Material of the tank, inner vessel/outer vessel | Stainless steel /Carbon steel | Stainless steel /Carbon steel | Stainless steel /Carbon steel | Stainless steel /Carbon steel | Stainless steel /Carbon steel |

| Insulation type | perlite-vacuum insulation | thermal blanket (insulation) | thermal blanket (insulation) | thermal blanket (insulation) | thermal blanket (insulation) |

| Design working life year | 20 years | 20 years | 20 years | 20 years | 20 years |

The model range, Table 1-2 – technical characteristics of semi-trailer Tanks – LARON

| Model | Semi-trailer Tank -26/0,3-ISO40 | Semi-trailer Tank -26/0,8-ISO40 | Semi-trailer Tank -29/0,3-ISO40 | Semi-trailer Tank -29/0,8-ISO40 |

| Capacity, m3 | 26 | 26 | 29 | 29 |

| Loading mass, kg | 19 344 | 19 344 | 21 550 | 21 550 |

| Loading rate (nitrogen/oxygen), % | 0,95/0,67 | 0,95/0,67 | 0,92/0,66 | 0,92/0,66 |

| Design pressure, MPa | 0,3 | 0,8 | 0,3 | 0,8 |

| Design temperature, С° | – 196 | – 196 | – 196 | – 196 |

| Material of the tank, inner vessel/outer vessel | Stainless steel / Stainless steel | Stainless steel / Stainless steel | Stainless steel / Stainless steel | Stainless steel / Stainless steel |

| Insulation type | thermal blanket (insulation) | thermal blanket (insulation) | thermal blanket (insulation) | thermal blanket (insulation) |

| Design working life year | 20 | 20 | 20 | 20 |

Products of “Soyuzprofmontazh” LLC

Tank discharge with a cryogenic pump.

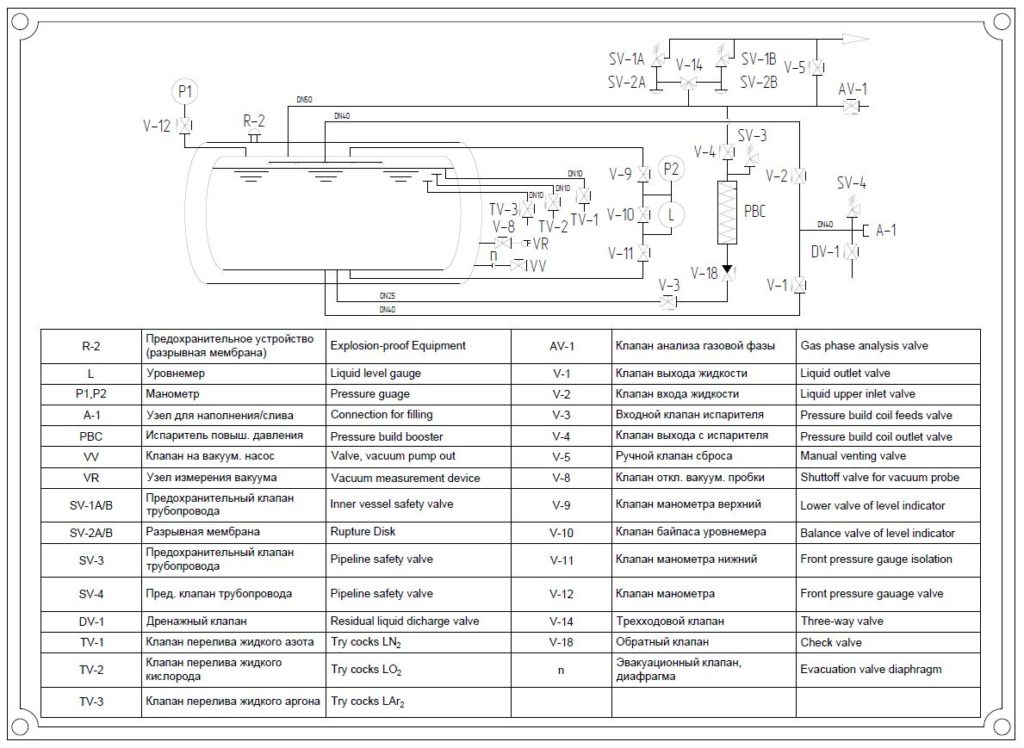

In the basic configuration, the cryogenic semi-trailer Tank is supplied without normally installed cryogenic pump and its discharge is carried out by pressure build-up with the help of evaporator installed at the bottom of the semi-trailer Tank.

To discharge (drain) the cryogenic liquid from a semi-trailer Tank, at the first stage, it is necessary to build-up the pressure by slow opening the inlet valve of the evaporator. On the diagram the inlet valve is marked up V3, then open the valve V4 and close the gas discharge valve V5. The liquid from the Tank will be piped to the evaporator whereby the necessary overpressure in the range of 0.5 to 1.7 bar will be created in the Tank. As soon as the pressure in the Tank is built up, it is necessary to start its discharge (drain) through A1, having connected a flexible cryogenic hose to it previously.

Optionally, according to the technical specification of the customer, the semi-trailer Tank can be equipped with a centrifugal cryogenic pump with an electric drive, that will allow the Tank to be discharged (drained) in volume of 29m3 per one hour, i.e 21.1 tons of liquid nitrogen or oxygen will be transferred from the Tank to the permanently installed storage vessels of the consumer in a short space time that will save your employees time for this operation.

Apart of all, application of cryogenic pumps will be convenient in operation of the Tanks in cases when it’ll be necessary to refuel several consumer facilities located at different addresses from one semi-trailer Tank. For example, the manufacturer of cryogenic liquid is located in one city, and the consumers – in the nearby city or suburb, in this connection the 29 m3 semi-trailer Tank will be the optimal solution, since for one transportation you will be able to transport the maximum quantity of the cryogenic product, and with the help of the pump you will be able to speed up filling / emptying process at many times.

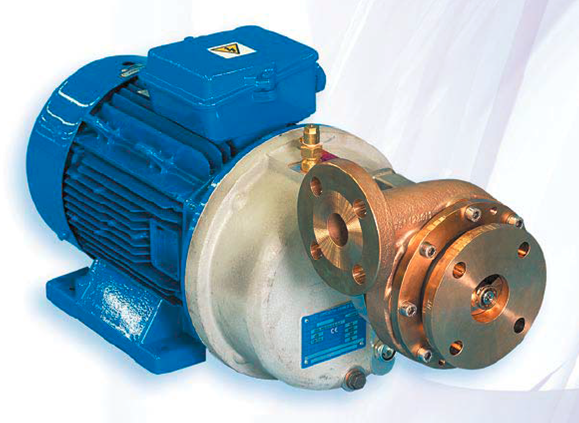

As a standard, we use cryogenic centrifugal pumps driven by a reducer from an electric motor. The pump is located on a special metal platform in the valve cabinet (rack) of the semi-trailer Tank. If it is necessary and for the convenience of the power supply connecting, we also offer to install an extension coil with an electric cable.

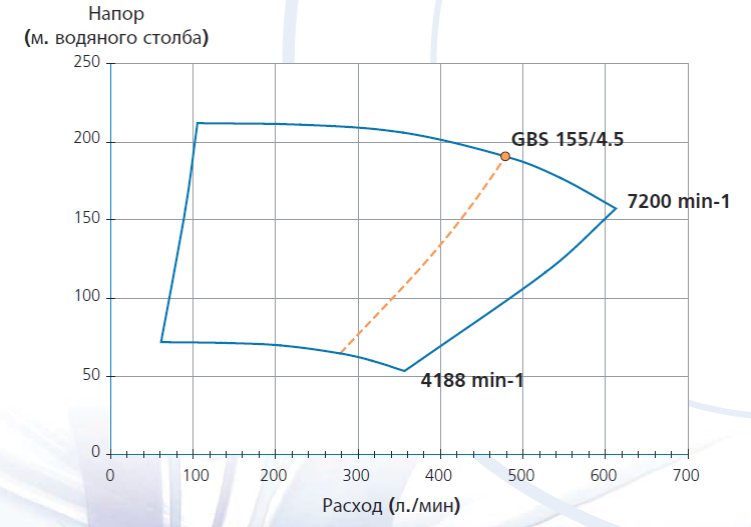

Basic parameters of the pump

Of course, the use a cryogenic pump will increase the cost of a semi-trailer Tank by 10-15%, but the final decision on the scope of supply is always made by the customer.

To get the cost of a semi-trailer Tank with cryogenic centrifugal pump!

|

Need consulting? |

|

|---|

|

«All equipment is certified» |

|

|---|

TAKE ON LEASE